The discovery of ‘infrared rays’ dates to the beginning of the 19th century by Sir William Herschel, He concluded through experiments that there is an invisible light that can heat objects. In 1963, 163 years later, the first thermal camera was invented. The thermal imager doesn’t rely on visible light but thermal radiation from the object. It converts it into thermal imaging that is visible to the naked eye through a series of signal processing.

It is initially limited to military applications because of its classified use and exorbitant prices. Around 2000, after decades of development, thermal imaging technology has gradually matured and is widely used for multiple applications. However, the price of this technology is still out of reach for most potential consumers today, and this article covers why that is.

While buying a thermal device, we look at the features and the price tag of the product and then compare it with others in the market. Thermal devices take the form of cameras, riflescopes, binoculars, etc. If you explore the marketplace, you’ll find that the prices of these devices are relatively high than standard day optics.

Now, this might come as a shock at first, but let’s explore what makes these devices so pricey. Here are some factors that decide the price point of different thermal equipment:

Let’s review the factors mentioned above in more detail.

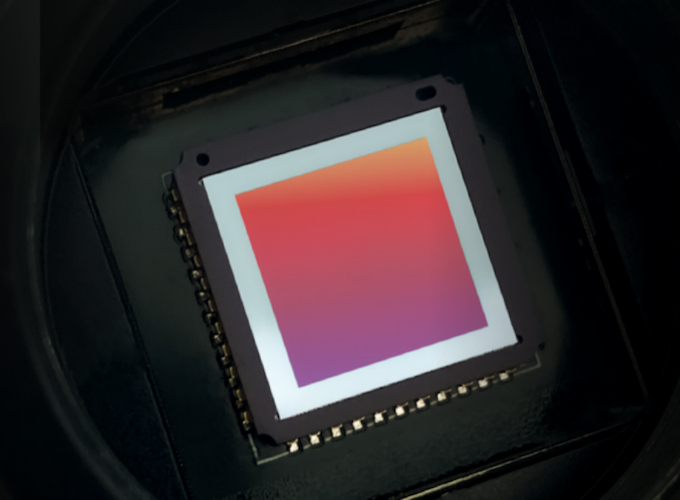

The detector is mainly composed of a microbolometer and related circuits. It’s responsible for receiving thermal radiation and converting it into a digital signal with radiation intensity information. The microbolometer is a grid of heat-sensitive materials atop a corresponding grid of silicon. Infrared radiation from a specific range of wavelengths strikes heat-sensitive materials such as vanadium oxide or amorphous silicon and changes its electrical resistance. This resistance change is measured and processed into temperatures which can be represented graphically by related circuits. The microbolometer grid is commonly designed and manufactured in three sizes, a 640×480 array, a 320×240 array (384×288 amorphous silicon), or a less expensive 160×120 array.

The detectors cost a lot because of their vulnerability to various environmental conditions, high power consumption, low mass production stability, and integration issues. Since the production of detectors requires high platform costs, the investment in technology research and development is also a sizeable continuous investment. The improvement of each parameter means the upgrade of the entire system. There is still much room for improvement in core indicators such as NETD, pixel pitch, and magnification, which leads manufacturers to continue to research and upgrade to ensure that they will not significantly lag behind their competitors.

Some high-quality thermal devices use germanium glass lenses. They have a high refractive index, allowing the IR range of wavelengths to pass through and reach the sensor that identifies a target.

Because of the rarity of the germanium metal, it costs 1500 dollars per kg; and that’s just the cost in its raw form. When you add the price of refining and processing germanium into a high-performance long-range thermal surveillance lens, the total cost of the equipment increases exponentially.

Also, it depends on the aperture (the F-number of the device); the lower the F-number is, the more expensive the lens costs. For example, an F1.0 lens is always costing more and has better performance than an F1.2 lens.

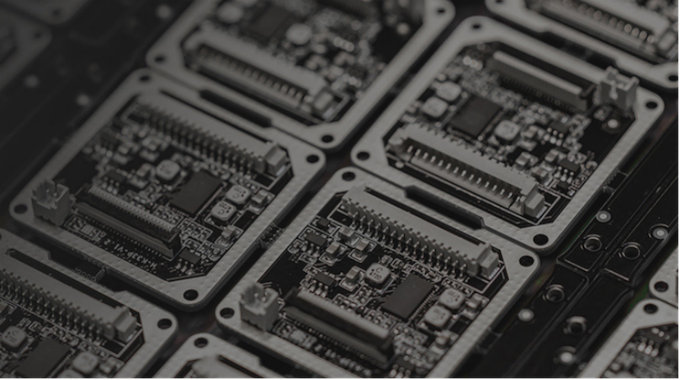

The FPGA is a hardware circuit that a user can program to carry out one or more logical operations. Precisely speaking, they are integrated circuits on a chip—that’s the “array” part. Those arrays are groups of programmable logic gates, memory, or other elements. The FPGAs within the thermal cameras filter and process signals generated by thermal detectors. Often, turning a new signal processing concept into an algorithm that runs in real-time on a production camera is a lengthy process, and it costs. However, a well-designed thermal imager always needs FPGA as the main advantage of an FPGA is the ability to change its functionality after a product has been designed. For instance, when the upgrade of the thermal algorithm is completed for improving the feature’s performance of the device.

Detectors used in thermal cameras do not receive the input in the same format as the screen. The input received by the cameras is in a format that is indecipherable by the human eye. Infrared cameras have sensors that map the environment based on heat signatures which are then translated into images that humans can understand. The technology behind this is entirely based on algorithms. The quality of image detailing and the accuracy of the temperature are determined by how well written the algorithm is. There is no one universal algorithm. Instead, each different application uses a specific algorithm to improve image clarity.

Image quality is always one of the most critical topics for thermal imaging equipment manufacturers. The development of an algorithm decides the image quality of a thermal device. Algorithms are customized according to the hardware specifications, for instance, the resolution of the thermal detector and the focal length. The algorithm is so specific that it is built into the camera. Since each camera model requires its proprietary code that requires specialists to do much testing during software development, it becomes an additional cost source that adds to the thermal device’s price tag.

The magnification level of the targets is related to the display quality of the thermal imagery too. The thermal riflescope user is always looking for a proper level of magnification to see targets in the best image quality and details. They are looking for a high magnification level device with the best image quality. However, too much magnification will significantly affect the image quality. Therefore, under the premise that the hardware is determined, the software algorithm becomes the main reason that decides how much the magnification can achieve. For example, how to reduce the interference of invalid heat sources while retaining the details of the target and how to keep the environmental information while highlighting the target will directly determine the user’s intuitive experience. These all increase the cost of the product.

While navigating the elements that factor in the making of thermal devices and their respective costs, we must also consider the value of the techniques used. These techniques involve the assembly and testing of thermal equipment.

When it comes to assembly, the production of IR devices requires specialized personnel with advanced studios and specific working environments that are dust-free and maintained at a constant temperature.

Quality is checked at every step with 100% precision to produce a qualified thermal imaging product. No thermal product can be packaged or sent out before passing various quality assurance tests, such as black body calibration and performance tests. A series of different precision inspections need to be done through expensive instruments to perform all these tests.

The Cryogenic Cooler is a component of the cooled thermal imaging system. Cooled thermal imaging equipment will have a qualitative leap in detection range and image quality by providing the detector with an ultra-low temperature working environment to improve the sensitivity significantly. Due to the cooled thermal imaging equipment is too expensive and is currently mainly used for military use. Still, it is also a type of thermal imaging equipment that this article must mention, so today, we will only explain this point of view and will not discuss it further.

From being a military technology to having widespread usage, thermal imaging has come a long way. Gone are the days when thermal imaging technology cost millions of dollars and was exclusive to military applications. Now they are used in a wide range of industries such as law & enforcement, home security, medical inspections, hunting, and even outdoor adventures. Some industries even use the technology in their manufacturing process to improve the quality of their products, like metallurgy.

Although thermal devices are expensive, it is essential to note that their performance is improving significantly over the years. The value they bring to us increases with the development of thermal imaging technology.