Our tests use pressure chambers, vibration stands, and shooting simulators to give us an accurate picture of how our products work in any setting. The precision offered by our lab and field tests allow us to comply with MIL-STD-810G equivalent, ISO 9001: 2015, and CE standards.

Senopex has applied its supply chain model across every device in the product portfolio spanning with absolute quality and delivery.

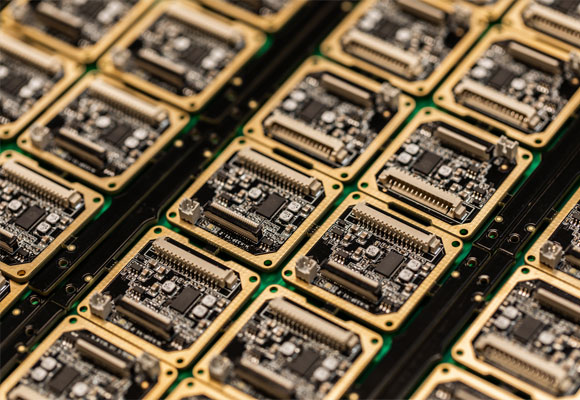

Here in Senopex, we are proud to design and manufacture thermal cores ourselves.

The thermal detectors of Senopex are designed and manufactured based on wafer materials from trustworthy suppliers like Lynred. In order to achieve even better performance such as high sensitivity, low power consumption, and overall reliability, Senopex conduct wafer-level packaging by ourselves thank the powerful and strong R&D team.

FPGA is sensitive to complex signals and can process multidimensional signals. As such, our engineers check on the quality of FPGA with the highest standard. Circuits are tested for overall voltage, temperature, and frequency ranges, allowing the highest data collection across functional components.

The OLED is tested with all the dots to observe the image quality indexes of our thermal devices, which include brightness, uniformity, and response. The tests help us look into how our device's efficiency consumes power while displaying clear and focused images.

Senopex commits to supply perfect thermal image displays. All parts from us use the highest quality materials designed to OEM standards.

The objective lens is the core component of a thermal imager. Senopex only offers a large aperture F1.0 germanium lens for every device in the product portfolio to achieve the perfect image quality.

To guarantee the best performance and transmissivity of the lens, we take full advantage of high-precision measurement equipment such as vibration-isolated optical benches and ultrasonic cleaners to perform a wide variety of tests, including the determination of optical and geometrical parameters and wavefront distortion measurements.

Senopex uses aircraft-grade hard-anodized aluminum alloy housing for all devices in the product portfolio.

In order to realize consistent reliability and maximum lifespan of the device. Our rigorous tests on the housing including physical testing, pressure test and electronic dimensional checking.

We provide specific requirements to test our thermal imagers, from detection distance to vibration tests, in order to verify their accuracy and durability.

The detection distances of our thermal scope and binoculars are tested in the field. According to the Johnson criteria, detection range at different distances is strictly evaluated to get the precise reading of the 'detection,' 'recognition,' and 'identification' range.

Same field tests are conducted in sunny, cloudy and rainy days to acquire the real data.

Senopex always working towards longer battery life of the devices. The DOT series thermal scope is able to reach industry-leading 14 hours continuous working time without the need of additional battery pack.

Our technicians test the device when features such as laser range finder, electronic compass, GPS, and other functions are on and off. Inspection and tests of battery life are simple and straightforward. All devices have to qualify its standard operation working hours before leaving the production line.

Set the temperature at 60℃, the high-temperature test lasts for two hours and determines if the device is functional under extreme heat. The devices qualify when features like brightness & contrasts control, image display, and other features are functional under these harsh conditions.

Set the temperature at -45 ° C, the low-temperature test lasts for two hours and determines if the device is functional under extreme cold. The devices qualify when features like brightness & contrasts control, image display, and other features are functional under these harsh conditions.

Passing through this test certifies that our devices are functional under extreme weather conditions with cold temperatures.

Setting the temperature to 40 ° C and the humidity at 95%, this test challenges the durability of our devices and how they resist varying levels of humidity.

Our devices are deemed ready when brightness & contrasts control, display of image and other features are functional under these conditions.

It refers to examining the anti-shock performance of the product under the expected use environment.

We simulate the various vibration environmental impacts encountered by the product in the transportation and use environment, the ability to dispose of the product to prevent different environmental vibrations. After multiple tests, the results show that the product is fully resistant to various environmental vibrations for daily use and transportation.

To qualify as a military standard thermal scope, our devices are able to endure up to 1200G recoil to be an unparallel model in the market.

We conduct shock test equivalent to the standard of MIL-STD-810G. The standard shock tests start from 300G to 1200G with the frequency of 300 times/100G/cycle.

Many Senopex thermal imagers are equipped with a built-in laser rangefinder. The LRF is one of the most powerful features to recognize targets distances in real-time.

We believe field tests are the only way to prove the final results to achieve long-range targeting and high measuring accuracy. We conducted rigorous tests in harsh conditions and extreme temperatures at different distances, such as rainy forests and deserts at temperatures between -40℃-60℃.

Our housing inspection tests the cleanliness and

scratch-resistance of our thermal imaging devices to ensure that they maintain a clean surface.

Senopex always offers useful accessories to our clients. Each year, we update the accessory package content. We conduct full inspection on all accessories piece by piece. A complete inspection verifies their durability and efficiency in their functions.

To maintain optimum quality, we trust only suppliers that provide the highest standard parts and components for our thermal imagers.

Our thermal imaging products need quality materials. We regularly audit our supplier base to maintain our production standards. The criteria we follow include delivery consistency, material quality, and proper processing.

To maintain a consistent quality among all of our thermal imaging products, we rarely replace suppliers. We form an agreement with our suppliers to guarantee that the materials delivered follow our requirements and industry certifications.